Microntech Kilews Electric Screwdriver Motor Working

Microntech Kilews Electric Screwdriver Motor Working

The main purpose of the electric screwdriver is the tightening of the application. Now a day’s electric screwdriver is performing well by its performance in various electronic as well as mechanical industries. Kilews electric screwdriver is very popular in terms of accuracy. Kilews screwdriver is not different from a conventional manual screwdriver, both serve the same purpose of tightening of application. But instead of manual operation, the electric screwdriver is having an electric motor to tighten the application very easily. These electric screwdriver work on the principle of clutch mechanism, in which the clutch is used to adjust the torque of the tool. Electric screwdrivers are two types based on the source of power supply. I.e. Brush type electric screwdriver and Brushless type electric screwdriver.

Brushless motor is having the best in performance, which is very efficient in working. It is a permanent magnet synchronous electric motor which is driven by direct current. It is having two parts: rotor and stator. The rotor is the rotating part whereas the stator is the stationary parts and consists of wire windings. In DC brushless motor permanent magnets are attached with the rotor on either side. This electromagnet performs to rotate the rotor and the supply comes with the stator. The working of a brush motor is slightly different from the brushless motor.

A brushed DC motor is having the structure in such a way that there is a spinning armature inside and a permanent magnet is outside of the structure. The permanent magnet which is outside is called the stator and the armature which rotates is called the rotor of the motor and the carbon brush is connected with the rotor which generates the electromagnetic field with magnets and rotor rotates. Basically, there are two types of brushless DC motor i.e. outer rotor motor and inner rotor motor. The basic difference between them is in design, they both do the same functionality

Inner rotor design

In this type of design, the rotor is placed at the center of the motor and the stator winding. Rotor magnet does not keep heat inside and the heat gets dissipated very easily. Due to this, this type of motor design produces a large amount of torque.

Outer rotor design

In this type of design, the rotor surrounds the winding which is placed in the core of the magnet. This type of motor operates at a lower-rated current and produces low torque.

The advantages of the brushless motor are: -

- The brush is absent, due to this there is no loss of energy due to friction and also increase the efficiency.

- DC brushless motor can be operated at a very high speed.

- It is noiseless and no pollution occurs.

- It can be accelerated and decelerate very easily because of low inertia.

- It has a high-performance motor and gives very high torque.

- These types of motor dissipate less amount of heat and cooled very easily.

Microntech is a channel partner for KILEWS products in India, having local sales and service support all over India. Microntech has a team of experts that can help you understand the torque process. It is a premier assembly solution provider in India with global experience. To know more about assembly solutions provided by Microntech please visit our website www.microntechgroup.com or you can contact your nearest Microntech branch by emailing at sales@microntechgroup.com to schedule a demo or a visit for any issues you are facing on your assembly line

Thank you for the information, it was a great article

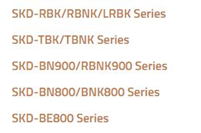

ReplyDeletekilews, kilews India, Kilews electric screwdriver