HOW TO INCREASE LIFE OF MICRONTECH KILEWS ELECTRIC SCREWDRIVER

HOW TO INCREASE LIFE OF MICRONTECH KILEWS ELECTRIC SCREWDRIVER

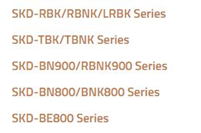

Microntech KILEWS developed industrial brushed and brushless

electric screwdriver series. KILEWS screwdrivers are compact, lightweight,

ergonomically designed, and easy to use, less noise, environment friendly. The heat generated by the motor is reduced and screwdriver performance is usually at the utmost level leading to reliable product

quality. KILEWS electric screwdriver ensures product quality, cost savings, and a big reduction in overall

failures.

PM of electric

screwdriver- Microntech KILEWS

provides the PM cycle for an all-electric screwdriver, for better performance and

increase life you need to follow these PM cycles. If PM of a screwdriver does not

done on time it may damage the internal spare parts of the screwdriver.

Standard Bit/Socket –

Always trying to use standard bit /socket with Microntech KILEWS screwdriver, these

standard bit/socket also provided by Microntech KILEWS. If the wrong bit/sockets

are used with a screwdriver, it may damage the shaft, bit sleeve, or another part of

the electric screwdriver.

Correct application or joint condition – Screwdriver selection

should be done according to the joint condition, because according to the joint

(soft, hard) torque also varies. If screwdriver does use in max position

torque setting higher than 6 on the torque scale, it will harm the internal

electronics part and the mechanical part of the screwdriver.

Hanging and torque

Arm – Microntech KILEWS electric screwdrivers are clutch shut-off type so the repulsive force is generated in the screwdriver after the tightening, to

overcome this problem and to protect the screwdriver Microntech KILEWS provided

torque Arm. For low torque series of electric screwdrivers doesn’t need to use

the torque arm but hanging is important, to protect the housing and cord of the

electric screwdriver from any interference from the assembly line.

Microntech is the premier assembly solution provider in India, which provides

the best results to manufacturers in sense of quality and accuracy with

services. Microntech has a presence everywhere in India and is a preferred

supplier for several manufacturers in India. To know more about assembly

solutions provided by Microntech please visit our website www.microntechgroup.com otherwise you can

contact your nearest Microntech branch by emailing at sales@microntechgroup.com to

schedule a demo or a visit for any issues you’re facing on your production

line.

Comments

Post a Comment