WHY USE ELECTRIC SCREWDRIVER OVER PNEUMATIC SCREWDRIVER?

WHY USE ELECTRIC SCREWDRIVER OVER PNEUMATIC SCREWDRIVER?

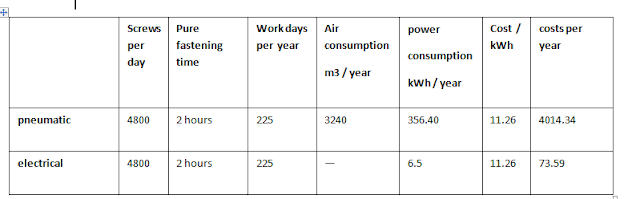

To operate the Electric screwdriver electricity is required

and to operate the Pneumatic screwdriver compressed air is required. Electric

screwdriver uses energy when it is needed hence it is efficient and approx no

loss of energy during the use of an electric screwdriver. But in pneumatic screwdriver

compressor is running to produce air which is wastes of energy.

Drawbacks of using a pneumatic screwdriver

Air Systems always have LEAKS which costs money because the compressor is still running to produce air which is wasted, the main drawbacks to pneumatic tools are Energy consumption because the source of power is air.• Cost- To operate the screwdriver need a compressor to giver power to the pneumatic tools, and the initial cost involved with this system compressor motor and pipe connection for air supply, etc, and also to provide the air supply need correct hoses and fittings and other additional accessories such as regulators and filters for a pure and fixed amount of air. Due to mechanical interference between parts, this decreases the life of the screwdriver, so maintenance costs also involve.• Air Pipe (hose)- Another main drawback is that you always need to have an air hose connected to your tools, which can limit where you use them and also air losses occur from the hose joints. Need to check all hose is ok or not because small leakage in hose decreases the performance of the screwdriver.• The compressor- compressor itself can be a drawback because compressors take time to fill, and it's generating noise. Because different tools require different amounts of air supply, so needed a more powerful compressor, generally, the compressor is larger in size, louder in working and more expensive.

Benefits of Electric screwdriver

Electric screwdriver only uses energy when it is needed hence EFFICIENT up to 90% savings so we tend to think of electric instead of pneumatic. Electric screwdrivers are worldwide, and come in a wide range of torque and have many benefits.• Convenience- Electric screwdrivers can simply be plugged in and used. They don’t require a whole lot of setup, and less maintenance required. When purchasing a corded electric tool, you don’t need to buy any additional equipment in order to run it.• Performance- electric screwdriver always gives the same result because there is a constant supply of DC. Electric screwdriver only uses energy when moving applying force (Torque).• Maintenance- Depends on usage and production, Electric screwdriver requires very less maintenance cost, during the first 1 year needs to do just greasing in gears.

Best Electric screwdriver

Electric screwdrivers are t best choice for all assembling lines and also if they need a speed great than that which they can achieve with a screwdriver. If you are interested in the implementation of industrial-grade, electric screwdrivers with smart tightening technology, KILEWS brushless, a high-precision screwdriver is just perfect for you.• Number 1 selling Electric Screwdriver Brand in India• Electric Screwdrivers with Brushless variant• High-speed models with two times the speed of Pneumatic screwdrivers• Noise-free and ergonomic operation• OK/NG signals available and line integration can be done• Error detection like cross-thread, double hit, etc. possible• High Carbon Steel clutch is used for super durable life• Available up to 50nm torque• Torque display variants also available.

I/O in KILEWS Electric screwdriver

To get KILEWS Electric Screwdriver

Microntech is a channel partner for

KILEWS products in India, having local sales and service support all over

India. Microntech has a team of experts that can help you understand the torque

process. It is a premier assembly solution provider in India with global

experience. To know more about assembly solutions provided by Microntech please

visit our website www.microntechgroup.com or

you can contact your nearest Microntech branch to schedule a demo or a visit

for any issues you are facing on your assembly line.

Comments

Post a Comment