DIFFERENCE BETWEEN ACCURACY & REPEATABILITY IN TERMS OF ELECTRIC SCREWDRIVER

DIFFERENCE

BETWEEN ACCURACY & REPEATABILITY IN TERMS OF ELECTRIC SCREWDRIVER

Now we talk

about the most confusing & most important topic of our industry that is

what is accuracy & what is repeatability & what is the difference

between them. These both the factor decides the working efficiency of any

product or any process. It also decides the quality of the Product then the quality of

work. So electric screwdrivers are clutch based mechanism, we set the torque

through torque ring in them. They include a spring in their clutch assembly,

when torque achieves then spring opens & pushes the pilot rod up then

screwdriver shuts. So there is no sensor inside it who senses the force during

fastening like in DC transducerized tools, they have the strain gauge to sense

the force. So now first understand the accuracy then this mechanism will easy

to understand.

ACCURACY

Accuracy is the correct working capability of anything, accuracy is hit near the goal all

time in changed conditions also. Like we talk about DC tools if we set 15Nm

(14-16Nm required) on soft joint and then result comes 14.5, 15.3, 14.2, etc.

& then set 15Nm (14-16Nm) on hard joint and got the same result, so this

is called good accuracy of the tool because here conditions were different one was

soft joint & one was hard joint but tool adjusts itself & gave same

result in the required band (14-16), hits near the target value always. So that’s

why we always concerned about the accuracy of DC tools, we never talk about

the repeatability, why let's discuss below.

REPEATABILITY

Repeatability

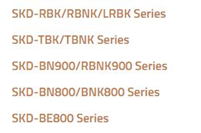

is hitting the target in the same line means always hit a goal in the same way but only in an unchanged condition. Now we talk about the KILEWS electric screwdriver who

has the high precise clutch assembly. If we required 15Nm (14-16Nm required) on

a specific joint so first we will set the tool on 15Nm on static tester like

KILEWS KTM tester, then run the tool on joint & if we are getting low

torque because of losses in joint then we increase the tool torque, then again

run & again check, and now if we getting the 15Nm, so our result comes

like this 14.9, 14.9, 14.9 14.9. And now if conditions changed like joint

changed or application changed so you will get different results may below be high, electric screwdriver can’t adjust itself according to the application ,

so it works better only in an unchanged condition. But it always hit the same

target again & again.

REPEATABILITY

Repeatability

is hitting the target in the same line means always hit a goal in the same way but only in an unchanged condition. Now we talk about the KILEWS electric screwdriver who

has the high precise clutch assembly. If we required 15Nm (14-16Nm required) on

a specific joint so first we will set the tool on 15Nm on static tester like

KILEWS KTM tester, then run the tool on joint & if we are getting low

torque because of losses in joint then we increase the tool torque, then again

run & again check, and now if we getting the 15Nm, so our result comes

like this 14.9, 14.9, 14.9 14.9. And now if conditions changed like joint

changed or application changed so you will get different results may below be high, electric screwdriver can’t adjust itself according to the application ,

so it works better only in an unchanged condition. But it always hit the same

target again & again.

So here is

the big difference in accuracy & repeatability, somewhere repeatability is

more important than accuracy. So electric screwdriver always have the

repeatability, it always hits the same target in an unchanged condition.

Comments

Post a Comment