MICRONTECH KILEWS BRUSHLESS SERIES IS VERY BENEFICIAL FOR BATTERY MANUFACTURERS

MICRONTECH KILEWS BRUSHLESS SERIES IS VERY BENEFICIAL FOR BATTERY MANUFACTURERS

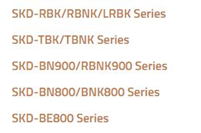

KILEWS developed

automatic industrial brushless electric screwdriver series. KILEWS

screwdrivers are compact, lightweight, ergonomically designed, and easy to

use, less noise, environment friendly with the dust-free operation. Brushless motors have a particularly

long operating life with no need for fixed time period maintenance or

replacement of expendable parts (carbon brushes, rotor, switches, and other

contact points). The heat generated by the motor is reduced and screwdriver

performance is always at the maximum level resulting in reliable product

quality. The brushless screwdriver provides product quality, cost savings, and a

discount in overall failures.

Other

screwdrivers are brush type electric screwdrivers and pneumatic screwdrivers

have some problem if any battery manufacturer used these screwdrivers. Carbon

is a good conductor of electricity, and in all brush-type electric screwdrivers, carbon brushes are used.

After a certain period, these carbon brush is rubbed and

the carbon powder may be emission in the assembling area of the manufacturing

line. If any battery manufacture does use the brush type electric screwdriver for

tightening the battery parts, then there is a chance to spark or short the

battery because of this carbon powder.

Another option for battery manufacturer is a pneumatic tool, pneumatic tools are running with compressed air and this dry

compressed air is may generate small spark during the operation because of

compressed air generates friction with the tool body, and this spark not good

for battery.

Working of the Most of pneumatic screwdriver is based on impact the mechanism, in impact mechanism, a small spark is generated because of friction and

this sparking may damage the battery parts or cells.

So

Microntech KILEWS brushless screwdrivers are very beneficial and suitable for

all battery manufacturers, because of these tools are durable, accurate and

there is no carbon dust present.

Contact

Microntech at sales@microntechgroup.com or visit website www.microntechgroup.com to know more about torqueing solutions from Microntech.

Comments

Post a Comment